PVDF पाइप

उत्पाद विवरण:

- प्रॉडक्ट टाइप अन्य

- कनेक्शन सॉकेट जॉइंट

- सतह का उपचार अन्य

- अनुभाग आकार गोल

- रंग सफ़ेद

- अधिक देखने के लिए क्लिक करें

PVDF पाइप मूल्य और मात्रा

- 100

- मीटर/मीटर

- मीटर/मीटर

PVDF पाइप उत्पाद की विशेषताएं

- सफ़ेद

- सॉकेट जॉइंट

- अन्य

- गोल

- अन्य

PVDF पाइप व्यापार सूचना

- 100 प्रति दिन

- 10 दिन

- Yes

- खरीदार द्वारा भुगतान किए गए शिपिंग और करों के साथ मुफ्त नमूने उपलब्ध हैं

- ऑल इंडिया

उत्पाद वर्णन

A PVDF Pipe is a thermoplastic pipe that expresses versatility for applications similar to other thermoplastics, particularly fluoro polymers. PVDF resin is heated and handled for use in extrusion and injection molding to produce PVDF pipes, sheets, coatings, films, and molded PVDF products, such as bulk containers. The PVDF is the four-letter acronym for Polyvinylidene Fluoride, one of the world’s toughest, most used high purity, synthetic materials. The Pipe is ideal for processing chemicals because they don’t react with the vast majority of solvents and chemicals. The offered PVDF Pipe is very efficient and strong.

Specification

| Minimum Order Quantity | 5 Meter |

| Single टुकड़ा Length | 3 meter |

| Color | White |

| Material | PVDF |

| Application | Chemical Handling |

| Size/Diameter | 4 inch |

| Brand | Nirmala |

| Processing /Physical Characteristics | Value | Unit | Test Standard |

| ISO Data |

|

|

|

| Melt volume-flow rate, MVR | 1.1 | cm3/10min | ISIO 1133 |

| Temperature | 230 | oC | — |

| Load | 5 | Kg. | — |

| Molding shrinkage, parallel | 2.0 | % | ISO 294-4, 2577 |

| Molding shrinkage, normal | 2.0 | % | ISO 294-4, 2577 |

| Mechanical properties | Value | Unit | Test Standard |

| ISO Data |

|

|

|

| Tensile Modulus | 2000 | MPa | ISO 527 |

| Yield stress | 50 | MPa | ISO 527 |

| Yield strain | 9 | % | ISO 527 |

| Nominal strain at break | >50 | % | ISO 527 |

| Charpy impact strength, +23oC | N | kJ/M2 | ISO 179/1eU |

| Charpy impact strength, -30oC | N | kJ/M2 | ISO 179/1eU |

| Charpy notched impact strength, +23oC | 22 | kJ/M2 | ISO 179/1eU |

| Charpy notched impact strength, -30oC | 5 | kJ/M2 | ISO 179/1eU |

| Thermal properties | Value | Unit | Test Standard |

| ISO Data |

|

|

|

| Melting temperature, 10oC/min | 169 | oC | ISO 11357-1/-3 |

| Glass transition temperature, 10oC/min | -40 | oC | ISO 11357-1/-2 |

| Temp. of deflection under load, 1.8 MPa | 104 | oC | ISO 75-1/-2 |

| Vict. Softening temperature, B | 138 | oC | ISO 306 |

| Coeff of linear therm, expansion, parallel | 150 | E-6/K | ISO 11359-1/2 |

| Burning Behav, at 1.5 mm nom, thick | V-0 | Class | IEC 60695-11/10 |

| Thickness tested | 1.6 | Mm | — |

| Burning Behav. at thickness h | V-0 | Class | IEC 60695-11/10 |

| Thickness tested | 0.8 | Mm | — |

| Oxygen index | 83 | % | ISO 4589-1/2 |

| Electrical properties | Value | Unit | Test Standard |

| ISO Data |

|

|

|

| Relative permittivity, 100Hz | 10.5 | — | IEC 62631-2-1 |

| Relative permittivity, 1MHz | 7 | — | IEC 62631-2-1 |

| Dissipation factor, 100Hz | 270 | E-4 | IEC 62631-2-1 |

| Dissipation factor, 1Hz | 2400 | E-4 | IEC 62631-2-1 |

| Volume resistivity | 2.3E10 | Ohm*m | IEC 62631-3-1 |

| Surface resistivity | 4E13 | Ohm | IEC 62631-3-2 |

| Electric strength | 27 | kV/mm | IEC 60243-1 |

| Comparative tracking index | 600 | — | IEC 60112 |

| Other properties | Value | Unit | Test Standard |

| Water absorption | 0.03 | % | Sim. to ISO 62 |

| Humidity absorption | 0.015 | % | Sim. to ISO 62 |

| Density | 1770 | Kg/m3 | ISO 1183 |

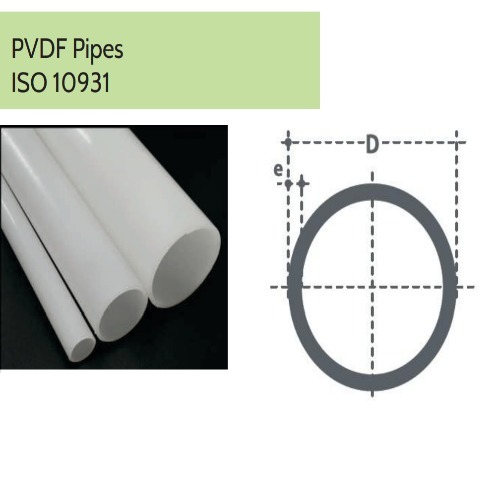

Pressure Rating

| SIZE | PRESSURE RATING | ||

| 10 kg/cm2 | 16 kg/cm2 | ||

| INCH | OD(MM) | THICKNESS(mm) | |

| ½†| 20 | 1.9 | |

| ¾†| 25 | 1.9 | |

| 1†| 32 | 2.4 | |

| 1 ¼†| 40 | 2.4 | |

| 1 ½†| 50 | 3.0 | |

| 2†| 63 | 2.0 | 3.0 |

| 2 ½†| 75 | 2.3 | 3.6 |

| 3†| 90 | 2.8 | 4.3 |

| 4†| 110 | 3.4 | 5.3 |

| 6†| 160 | 4.9 | 7.7 |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+